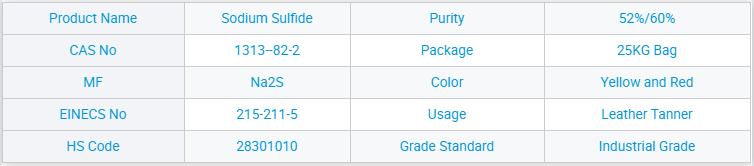

Technický síran sodný 60 Na2s 1313-82-2 Vločkový síran sodný

Naším cílem je poskytovat špičkové produkty a řešení za konkurenceschopné ceny a prvotřídní podporu zákazníkům po celém světě. Jsme držiteli certifikací ISO9001, CE a GS a striktně dodržujeme jejich specifikace kvality pro technický sulfid sodný 60 Na2s 1313-82-2 vločkový sulfid sodný. Naším konečným cílem je vždy se řadit mezi špičkové značky a také být průkopníky v našem oboru. Jsme si jisti, že naše produktivní zkušenosti s výrobou nástrojů si získají důvěru zákazníků. Přejeme si s vámi spolupracovat a vytvářet s vámi ještě lepší dlouhodobé vztahy!

Naším cílem je poskytovat vysoce kvalitní produkty a řešení za konkurenceschopné ceny a prvotřídní podporu zákazníkům po celém světě. Jsme držiteli certifikátů ISO9001, CE a GS a striktně dodržujeme jejich standardy kvality. Pokud máte zájem o některý z našich produktů a po prohlédnutí našeho seznamu produktů, neváhejte nás kontaktovat s dotazy. Můžete nám poslat e-mail a kontaktovat nás s žádostí o konzultaci a my vám co nejdříve odpovíme. Pokud je to snadné, můžete najít naši adresu na našich webových stránkách a osobně nás navštívit pro více informací o našich produktech. Jsme vždy připraveni navázat dlouhodobou a stabilní spolupráci s potenciálními zákazníky v souvisejících oblastech.

Hlavní zařízení pro výrobu sulfidu sodného s minimální koncentrací sulfidu sodného 60 %

Hlavní zařízení pro výrobu sulfidu sodného s minimální koncentrací sulfidu sodného 60 %

Horizontální zplyňovací pec s fluidním ložem: Ø360×1200 mm, 3 jednotky

Nádrž na rozpouštění alkálií: Ø230×1000 mm, 3 sady

Pračka zbytků: Ø230×1000 mm, 3 sady

Nádrž na koncentrovaný solankový roztok: Ø150×1800 mm, 3 sady

Odpařovací koncentrátor: Ø220×450 mm, 3 sady

Vločkovací nádrž: Ø1800×140 mm, 3 jednotky

Odlupovací stroj: D320, 3 jednotky

Pomocné zařízení pro výrobu síranu sodného s minimální koncentrací 60 % síranu sodného

Vodou chlazený struskový šoupátkový ventil: 2 jednotky

Systém chlazení cirkulující vodou: 3 sady

Systém spalování uhelného plynu: 3 sady

Automatický systém regulace uhelného plynu: 3 sady

Vykládací vozidlo: 3 jednotky

Systém krmení: 6 sad

Čerpadlo a ventil pro dopravu solanky: 3 sady

Vodou chlazený automatický odlupovací systém: 3 jednotky

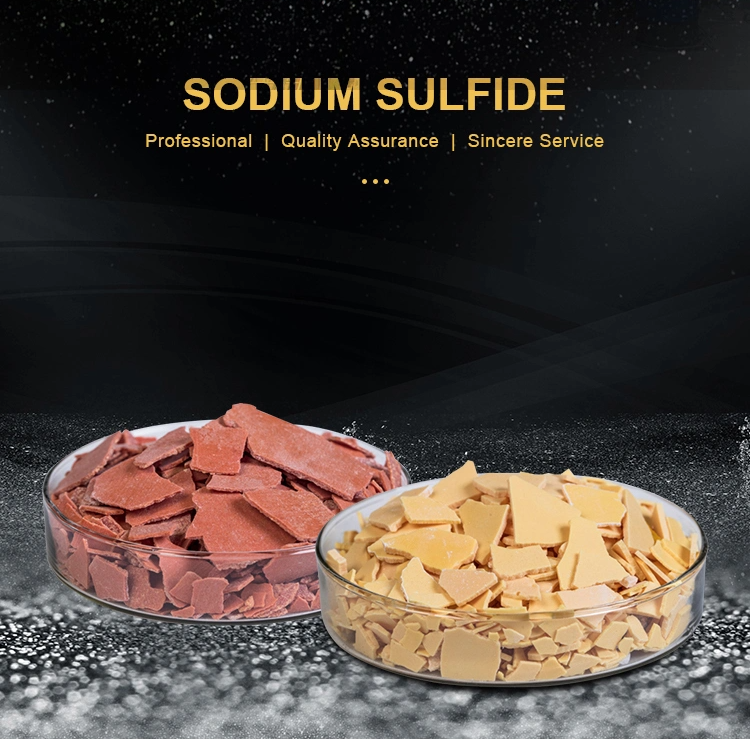

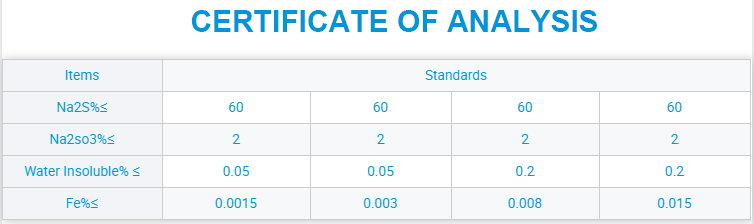

Vzhledem k potřebě odolnosti proti korozi, snadné výměně a dostupnosti materiálů se obecně používají plechy z uhlíkové oceli. Specifické komponenty, jako je odlupovací stroj, jsou vyrobeny z nerezové oceli, nože jsou potaženy PTFE (teflonem) a vyzdívka pece používá žáruvzdorné materiály s vysokým obsahem oxidu hlinitého. Síran sodný 60 % min. Síran sodný